Product Specification - Abrasion Rating?

A double rub rating is not applicable to a fabric used for bedding, curtain, drapery or other applications where the fabric is not subjected to abrasion. A double rub rating applicable to fabric used for upholstery is obtained from an industry test that measures fabric resistance to typical abrasion that is expected from the use of upholstered furniture.

General Guidelines for Residential Upholstered Furniture:

Under 5000 Double Rub Rating or code "LD" is suitable for home decor light duty upholstery use (not daily use, more for decorative appeal).

5000 - 14900 Double Rub Rating or code "MD" is suitable for medium use home decor upholstery applications such as living rooms.

15000 - 29900 Double Rub Rating or code "RD" is suitable for everyday regular and heavy use home decor upholstery applications.

30000 and Above Double Rub Rating or code "HD" is suitable for residential and commercial upholstery subjected to "extreme use".

Code "LDO" indicates a selection of fabric that is only recommended for 'light duty outdoor' upholstery applications where cushions do not receive regular use and can be easily removed and stored away from harmful UV light when not in use. These selections are not intended for normal indoor furniture upholstery as they are not constructed to withstand the abrasion of regular use. If you are in need of a more durable outdoor fabric that can also be used for indoor upholstery, we recommend a High Performance Indoor-Outdoor Fabric from Sunbrella, Bella-Dura and Covington.

General Guidelines for Commercial Upholstered Furniture:

The surface wear of a fabric caused by rubbing and contact with another fabric. Association For Contract Textiles "ACT" GUIDELINES General Contract Upholstery ASTM D4157-02 (ACT approved #10 Cotton Duck) 15,000 double rubs Wyzenbeek method ASTM D4966-98 (12 KPa pressure) 20,000 cycles Martindale method Heavy Duty ASTM D4157-02 (ACT approved #10 Cotton Duck) 30,000 double rubs Wyzenbeek method ASTM D4966-98 (12 KPa pressure) 40,000 cycles Martindale method End use examples of heavy-duty installations where upholstery fabrics rated at 30,000 double rubs should be appropriate are single shift corporate, hotel rooms/suites, conference rooms and dining area usage.

ACT acknowledges that there are extreme wear situations that may require higher levels of abrasion resistance. End use examples that may require higher than 30,000 double rubs include: 24 hours transportation terminals, 24 hour telemarketing, 24 hour healthcare emergency rooms, 24 hour casino gambling areas, and such public gathering places as theatres, stadiums, lecture halls and fast food restaurants. It is strongly suggested that double rubs exceeding 100,000 are not meaningful in providing additional value in use. Higher abrasion resistance does not necessarily indicate a significant extension of the service life of the fabric.

The Wyzenbeek and Martindale tests are the two methods commonly used to predict wear-ability. Actual performance is determined by many factors such as fiber content, weaves, finishes, furniture design, maintenance, cleaning, and usage. Durability of an upholstery fabric is a complex interaction (combination) of a number of performance tests that, in addition to abrasion, includes seam slippage, pilling, tensile strength, and usage. There is no correlation between the Wyzenbeek and Martindale tests so it is not possible to estimate the number of cycles that would be achieved on one test if the results from the other test were known.

TEST METHODS ASTM D4157-02 Oscillatory Cylinder (Wyzenbeek) The ASTM D4157-02 is a test of the American Society of Testing and Materials. A Wyzenbeek machine is used for this test allowing samples of the test fabric to be pulled tight in a frame and held stationary. Individual test specimens cut from the warp and weft direction are then rubbed back and forth using an ACT approved #10 cotton duck fabric* as the abradant. The number of double rub cycles achieved before two yarn breaks occur or noticeable wear is observed is recorded as the fabrics abrasion rating.

The wire screen abradant is recommended by ACT for use with vinyl and polyurethane coated upholstery and may also be used for testing 100% olefin fabrics.

ASTM D4966-98 Martindale The ASTM D4966-98 is a test method of the American Society of Testing and Materials (ASTM). This is an oscillating test. Fabric samples are mounted flat and rubbed in a figure eight like motion using a piece of worsted wool cloth as the abradant. The number of cycles that the fabric can endure before fabric shows objectionable change in appearance (yarn breaks, pilling, holes) is counted. Number of cycles determines abrasion rating.

WATER

WATER  60,000 DOUBLE RUBS

60,000 DOUBLE RUBS Passed Industry Standards

Passed Industry Standards

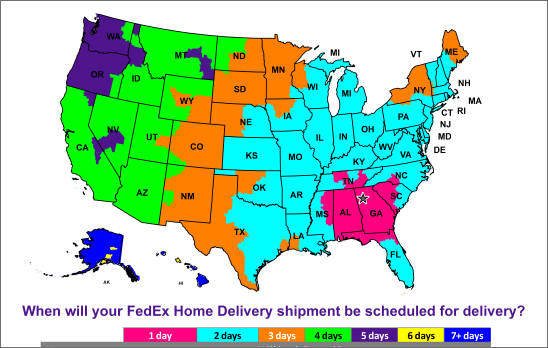

We apologize that our order processing has not been consistent during this pandemic and please know that we are working very hard to return to quick and consistent order processing. Our distribution center is operational and is currently processing orders as indicated below:

We apologize that our order processing has not been consistent during this pandemic and please know that we are working very hard to return to quick and consistent order processing. Our distribution center is operational and is currently processing orders as indicated below: